Innovative letter return material

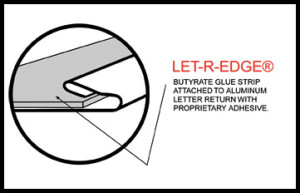

While widely used today in letter fabrication, the application of aluminum coil to channel letter fabrication was a sign industry first when Channelume was introduced by Heath signs Northwest in the 1970’s. In addition to this innovation, the coil is machine roll formed into a patented configuration, making the lighter weight letter return Channelume / Let-R-Edge structurally equivalent to heavier gauge metals. This contributes to superior hand forming characteristics, one of the developer’s original goals. Another distinctive feature is the inclusion of a means for attaching the aluminum letter return directly to the letter face to form the “channel” in one operation. The elimination of the trim cap application is a labor saving feature that is exclusive to the Channelume/Let-R-Edge channel system. Innovative fabrication scheme Since Channelume and Let-R-Edge aluminum coils are furnished “fabrication ready,” industry standard sheet metal letter fabrication techniques are replaced with simplified assembly system, using inexpensive system tools and equipment. It is also a “wrap it once” fabrication system. The face is fit and wrapped with the letter return one time to complete the channel. The extra fitting and wrapping a letter face with a trim cap is not required.LetREdge Material is available in three widths and a variety of colors to suit any design application.

The Channelume/Let-R-Edge System does not follow the standard sign industry sheet metal model for channel letter fabrication. The system is tailored specifically for channel letter signs with polymeric faces and embodies a number of innovations for efficient production of this type of channel letter.